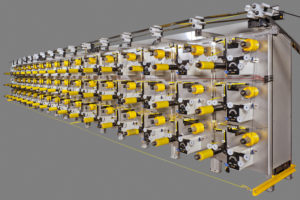

Smartwinder-XL™ spooling system for thermoset prepreg with interleaf capabilities illustrating 3 Vertical x 16 Horizontal = 48 spooling positions

Aerospace

Advanced Machines For Advanced Composites

PREPREG – CARBON FIBER PROCESSING SYSTEMS:

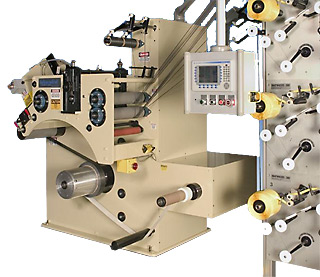

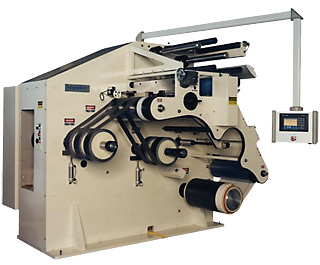

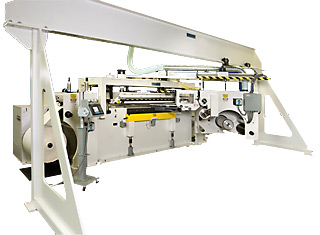

- Slitting & Computerized Traverse Winding Systems

- Zero Backbend Slitter/Rewinders

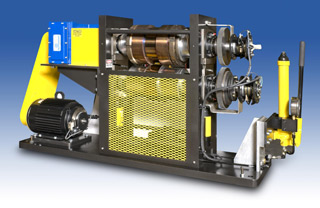

- Hot Melt Coater/Laminator

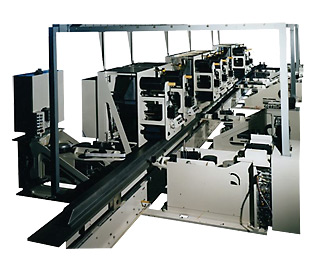

- Multi Drum Composite Pullers

- Multi Axis Cross Ply Assembly Equipment