Video Library

Browse videos from our video library.

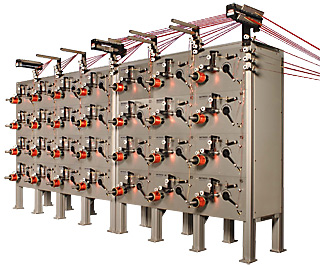

Smartwinder-XL™ Systems move the spool under the fixed input of material to eliminate skewing and ensure winding material maintains lateral position from the process to the spool.

Edge Trim Traverse Winders

Edge Trim Traverse Winders