Useful Links

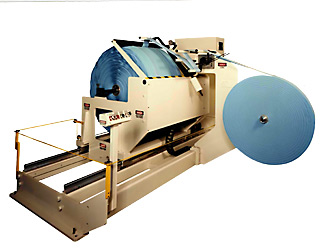

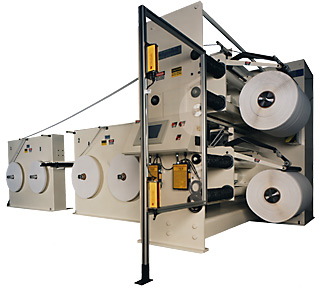

Offline Traverse Winders

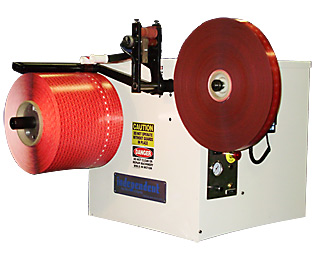

Spooling Machinery (Pancake To Spool)

Winds most material including paper, film, foil, nonwovens, PSA, & foam

Common Features:

- Adjustable Tension Control

- Smartwinders Software for Various Spool Shapes, Size and Winding Patterns

- Hand Held Operator Terminal For Computerized Traverse Adjustments

- Interchangeable Product Guides (Wheels or Shoes) for Various Widths

- Accommodates a Variety of Core or Flanged Spool Sizes

- Rugged, Compact Construction